Although generally small in size and individual cost, the unheralded ‘fastener’ can be responsible to a manufacturer for inefficiency, underproduction, lost component availability, downtime and no-build conditions that all threaten revenue and profits.

This is especially true at the starting point of design when important decisions on the correct type of fastener selection are made. Quite often, the manufacturer focuses on the functional aspects of their product without consideration being given to the type of fastener that will provide the best opportunity to optimise the assembly process when full production commences

TFC Europe Ltd is one of the leading suppliers of technical fastener components to industry, with an unrivaled reputation for delivering innovative products, supply solutions, and exemplary service, to help customers achieve breakthroughs in product development and new standards of manufacturing efficiency. As a company that has been in existence for over 50 years we recognise early consultation at the design stage allows some significant benefits:

Increased Option Availability – the later the assembly method is selected, the fewer options the manufacturer will have leading to more limited, expensive, solutions that may include additional tooling

Standard Solution Selection these are the ultimate preferred fastener solutions for any manufacturer and the earlier the collaboration, the greater the chance we can offer guidance towards a standard solution and avoid the need to supply a bespoke part. We are an independent company with a vast supplier base to hand and we can offer unbiased advice on the best fastener for the job.

Optimised Assembly – as a fastener specialist, we have the experience needed to determine if a better alternative solution can be found. Although manufacturer’s Design Engineers may be experienced in assessing the project from a fastener perspective, they may overlook specific requirements that can impact on the assembly and production.

Joint Consultation working in tandem with a fastener supplier like TFC allows both companies to share relevant information about their respective industries. We can offer new fasteners or joining technology whilst the manufacturer can advise on new industry requirements that may affect assembly methods.

On-Going Improvement by being given first hand access to the production line, manufacturers benefit by being advised on the latest fastening solutions available and how these can be integrated into the production process

Best Practices – by working with us we are able to identify which products work best for the manufacturer’s assembly requirements and these can then be made standard for future designs. In return, assembly costs can be lowered, assembly time cut and inventories reduced.

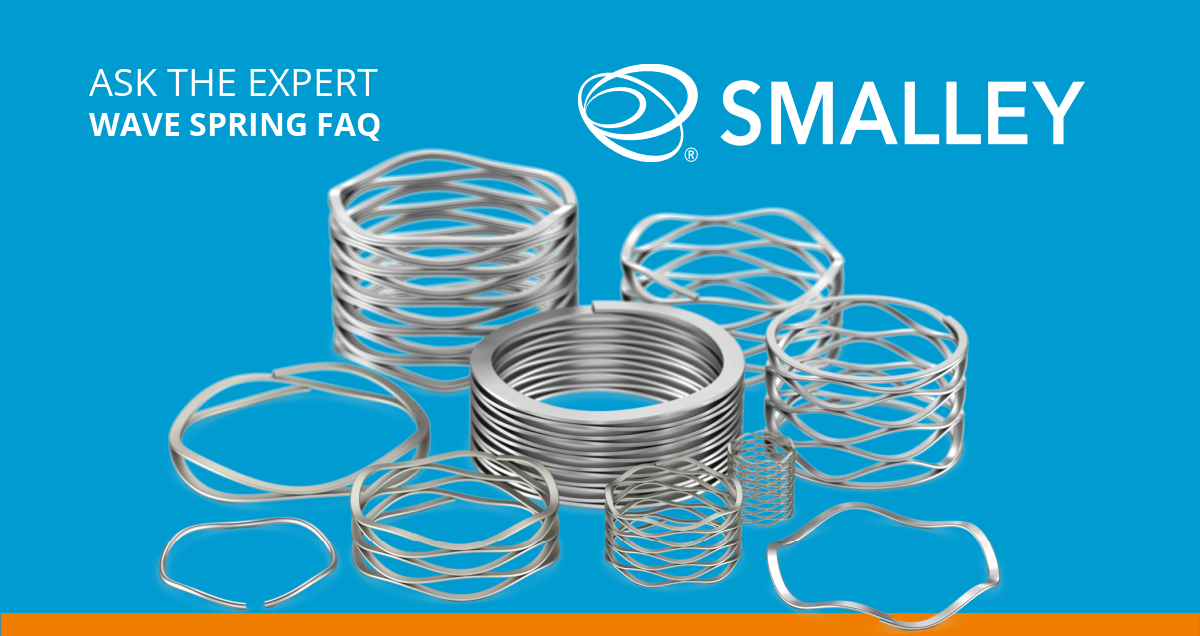

Product Awareness TFC offer bespoke seminars on a variety of specialist fastener and spring products which raise awareness within the manufacturers design and production staff of the product’s function, benefits and selection criteria

TFC is a leading supplier of technical fastening solutions employing over 100 staff throughout the UK and Germany. Our field and office based engineers offer a day-to-day consultation service with customers and prospects in order to combine our expertise with their specific skills and provide solutions to fastener problems on a long term partnership basis.

Call or e-mail now for more information.

T:- +44 01435 866011

e:- sales@tfc.eu.com

w:- www.tfc.eu.com

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.