Welcome back to Smalley Talk, where TFC engineers answer commonly asked Retaining Ring and Wave Spring design questions. This week, Justin Lawrence takes some more questions about Retaining Ring design, and how to ensure the groove geometry is correctly specified.

How important is the groove geometry?

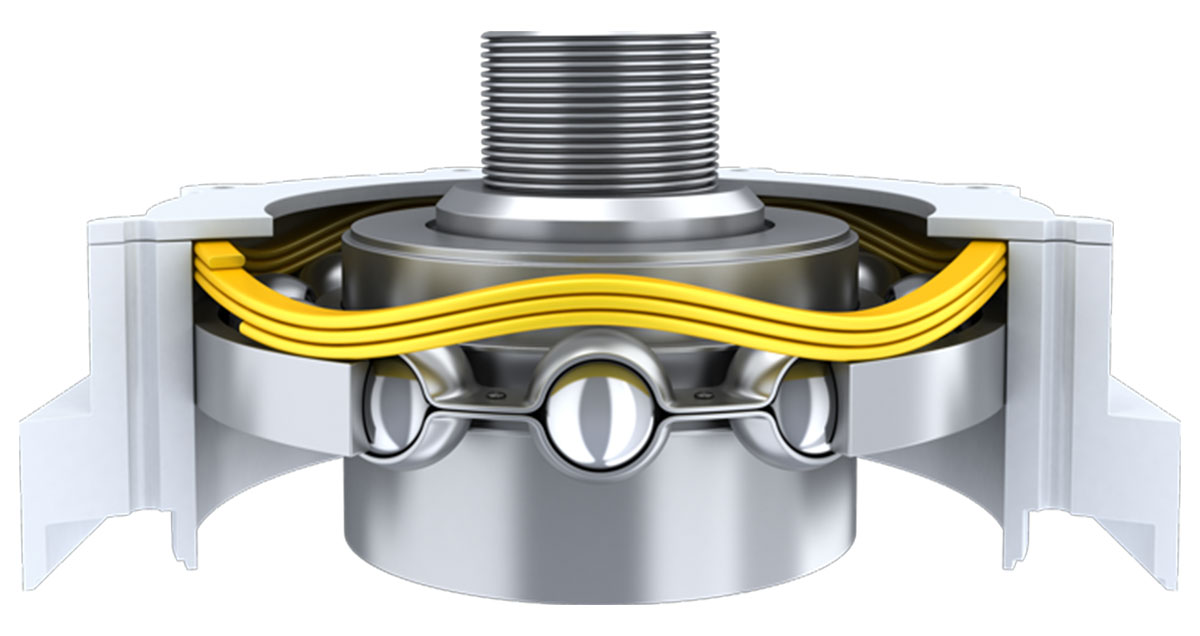

To assure maximum load capacity it is essential to have square corners on the groove, and a correctly specified radius in the bottom of the groove. The maximum recommended groove corner radius for a Retaining Ring with a diameter up to and including 25mm is 0.10mm. For Retaining Rings with a diameter larger than 25mm, the groove radius can increase to 0.25mm (max).

Can you provide a rule of thumb for how much distance there should be between the end of a pin/bore and the groove?

The general rule for the edge margin or the distance from the end of the pin (or housing) to the groove wall should be approximately 3 times the groove depth. This ensures there is sufficient material to support load on the Retaining Ring.

In all these cases there may be a specific requirement to take into account. Detailed calculations can be checked by our engineering staff, these will take into account shaft/housing materials and also the actual diameters specified in the application.

That™s all for now, check back next time when Simon Ward will answer questions about Wave Spring performance. Ask your own question for it to be featured in next month’s Smalley Talk here!

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.