Welcome to our Smalley Product Blog, where our engineers answer commonly asked ring and spring design questions. This week Simon Ward, Product Manager, fields some questions about small diameter wave springs and different uses for Smalley rings. He discusses applications for retaining rings, how they can be adapted to different uses, and when it might be better to select a more specialised product.

For more than 35 years TFC have represented Smalley, the global industry leader in the design and specification of retaining rings, snap rings, and wave springs. TFC’s team of engineers have the same extensive product knowledge and training, so whether you require a standard part or a customized solution, our dedicated team can solve design issues and help optimise the advantages of using Smalley products to enhance your design.

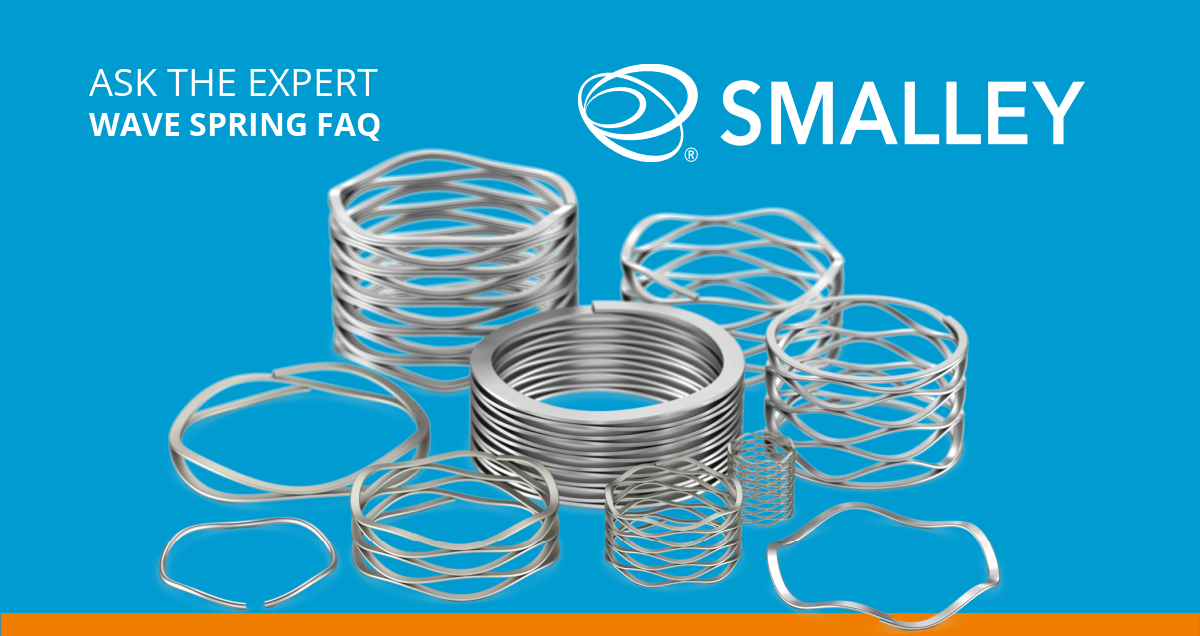

How small can a wave spring be manufactured and still function in my application?

Our smallest off-the-shelf range of wave springs, are designed to suit a 6mm diameter bore. If this is too big or the spring characteristics are not quite what you require, we can reliably edgewind custom designed wave springs with diameters as small as 4.5mm. At these small diameters every design parameter has a significant effect on the final design. We will ask about working lengths, deflection, loads, and the application requirements, TFC’s dedicated engineering team are available to discuss your specific application requirements and will design the right spring for your needs.

Depending on the diameter and the level of sealing required by the application, it may be possible to use a Spirolox retaining ring although they are not designed for that use. Spirolox retaining rings are manufactured with a circular form to cling in, or on a specified groove diameter, providing a shoulder.

Smalley™s Laminar Seal Rings utilise different cross sections and a minimal cling to ensure the circumference has maximum engagement with the sealing bore or shaft diameter. A more complete seal can be created using a series of these rings to create a labyrinth. Regardless, neither type of ring is intended to be used to seal against pressurized gas or fluid. They are a primary barrier to restrict the ingress on dirt in harsh environments. For more information, see our Laminar Seal Rings section or contact a TFC engineer.

That™s all for now. In the next installment we’ll cover Wave Spring tolerance and load characteristics. Stay up to date with all of this and more by signing up to receive future posts directly in your inbox. SUBSCRIBE HERE

Why not contact our team of engineers on +44(0)1435 866011 or email sales@tfc.eu.com

Latest News From TFC

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.

Catch up on all of the latest supply chain, fastener industry and company news from TFC Ltd.